Constant innovation within the plastics industry means that plastics are used across almost every sector, with a multitude of uses across construction, transport, electrical and of course packaging.

Anyone with health and safety responsibilities in plastics manufacture needs to minimise and control plastics fume during moulding, extrusion and similar processes. This article emphasises the need to reduce fume formation by maintaining plant and following recommended processing parameters such as process temperature and residence/dwell time, correct melt temperatures, operation and procedures, ventilation and more.

Protect your employees

It’s crucial for businesses like plastics recyclers, polymer suppliers and distributors, additive suppliers, service providers, plastics processors, packaging manufacturers and equipment suppliers for example, to ensure that the plastic fumes exposure on their workforce is controlled, safe and within legislation. By understanding the fumes and their by-products produced during manufacturing it will reduce the damaging effects that these can have on employee health and allow for the correct exposure control and procedures to be put in place. Fume production is influenced by:

- Material being processed

- Residence/ Dwell times

- Operating procedures, including purging;

- Reliability of temperature control

- Machine/screw maintenance.

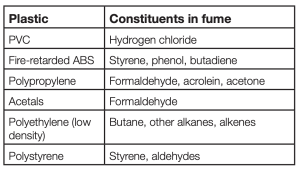

Examples of commonly processed plastics and constituents in fume:

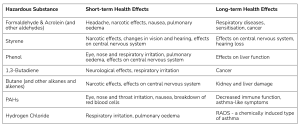

The effects of plastic fumes exposure on your workforce

For industries manufacturing and processing plastics, dust exposure from handling plastic pellets, granules and powders may be an obvious risk within the workplace. However, controlling dusts may not be sufficient for ensuring the protection of workers’ health. When plastics are heated – perhaps during mixing, extruding or heat treating – several plastic by-products are released as fumes.

These by-products can include aldehydes, styrene, hydrogen chloride and polyaromatic hydrocarbons (PAHs), regular or prolonged exposure to which can cause lasting health effects. Many constituents of plastic fumes have been linked to respiratory illnesses, sensitisation and even the development of cancers.

HSE Guidance for controlling fume during plastics processing

HSE have released a comprehensive document (View HERE) for businesses working within the plastics industry and the guidance supports health & safety operatives within these businesses to understand all aspects of the manufacturing process and how to minimise fumes produced with a checklist that aims to do just these, exploring the below;

- Information on the material

- Processing and Operational Procedures

- Machine Cleaning

- Machine/screw maintenance

- Temperature control

- Maintaining control measures

- Emergency procedures

Compliance with COSHH industry regulations

Under COSHH regulations, employers have the duty to ensure exposure to these plastic fumes are suitably controlled and, in the case of substances which can cause cancer or asthma, control exposure should be as low as reasonably practicable.

We can help your organisation when it comes to compliance and regulations by providing plastic fumes monitoring & analysis services. We provide a thorough assessment program for plastic fumes including;

- Evaluating your employees’ exposure levels to plastic fumes

- Evaluating the existing engineering control measures

- Carrying out checks of the implemented procedures

- Ensuring that you as a duty holder are fully compliant with the current regulatory requirements

*This list is not exhaustive

Safety First’s occupational exposure monitoring

Exposure monitoring is needed for work with harmful substances, such as plastic manufacturing. No matter how complex the issue, Safety First can find the right sampling strategy for you.

Our experienced team has extensive experience in monitoring plastic fumes, and have an in-depth knowledge of the associated risks to the health of your workforce. We understand that each business & environment is unique, so our plastic fumes monitoring solutions are tailored to your organisation’s bespoke requirements.

Safety First is experienced in delivering a complete range of occupational exposure monitoring services to provide you with confirmation that your control measures are adequate and workplace exposure limits are not exceeded.

Contact our friendly team of experts to find out more about occupational exposure monitoring or any of our other services.